Pellet Feed

Pellet Feed

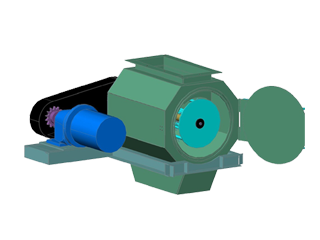

Pelleting is a process in which mixed feed in powder form is converted into pellets by mechanical compression in combination with moisture and heat. Process is achieved by a set of rolls and die of suitable hole size and shape. As the die & roll rotates, the product passes through the nip of roll & die and pressed into the die holes to make pellets.

Significance :

Today, the process is widely used because of both the physical and nutritional benefits of it.

Physical benefits :

We can count-improved ease in handling , reduced ingredients segregation , less feed wasage and increased bulk density.

Decreased feed wastage, reduced selective feeding , decreased ingredients segregation, less feed and energy expended on prehension, destruction of pathogenic organism ,thermal modification of starch and protein, improved palatability.

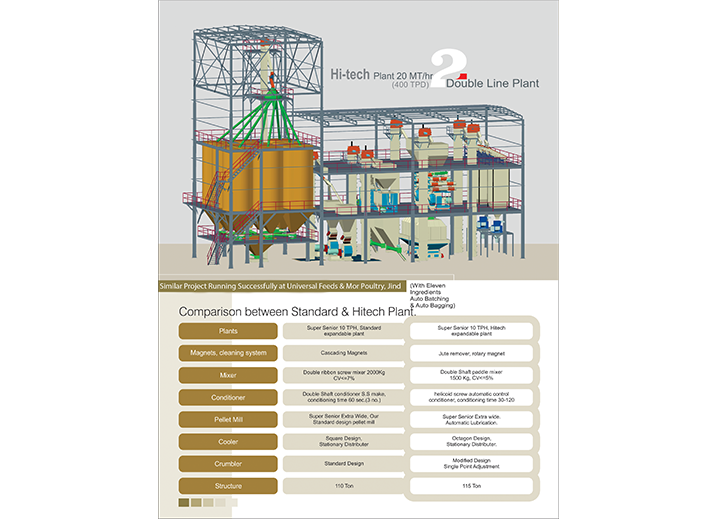

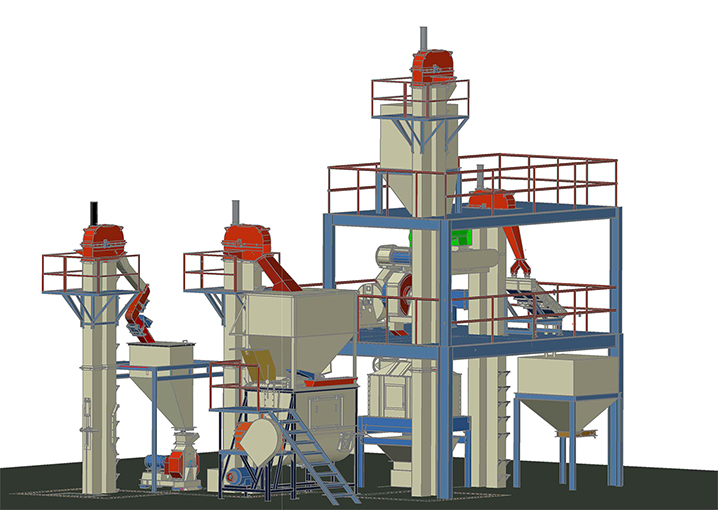

Desired features in pelleting plant for optimum pelleting

Pre-cleaning:

Batching:

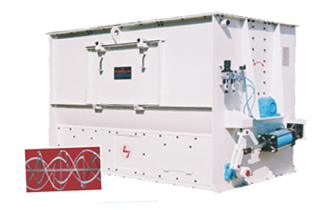

Mixing:

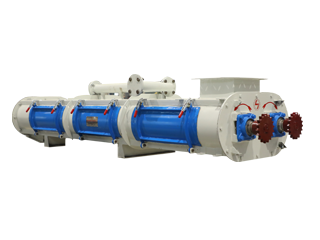

Conditioning:

Pelleting:

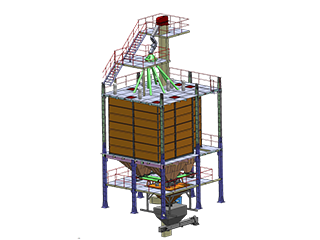

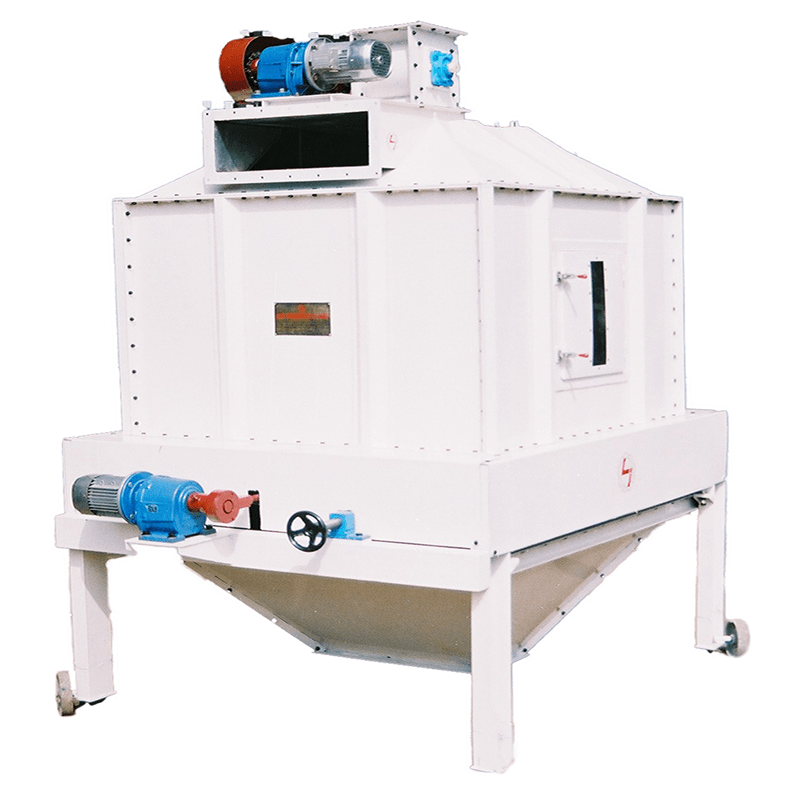

Cooling:

The desired feature of an efficient cooler are: It should be capable to remove the unwanted heat and moisture from pellets to improve its shelf life. The cooling should be uniform from all the sides.

Crumbler:

Screening:

Bagging:

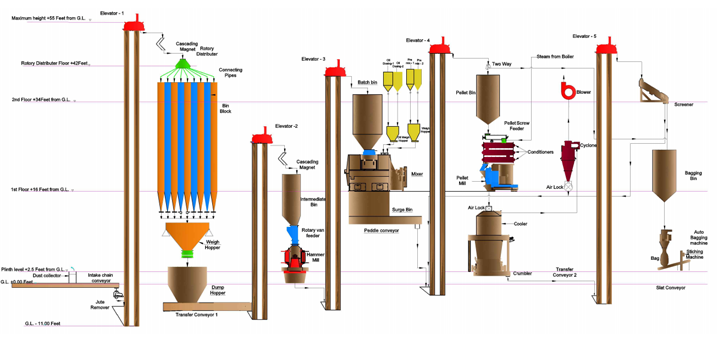

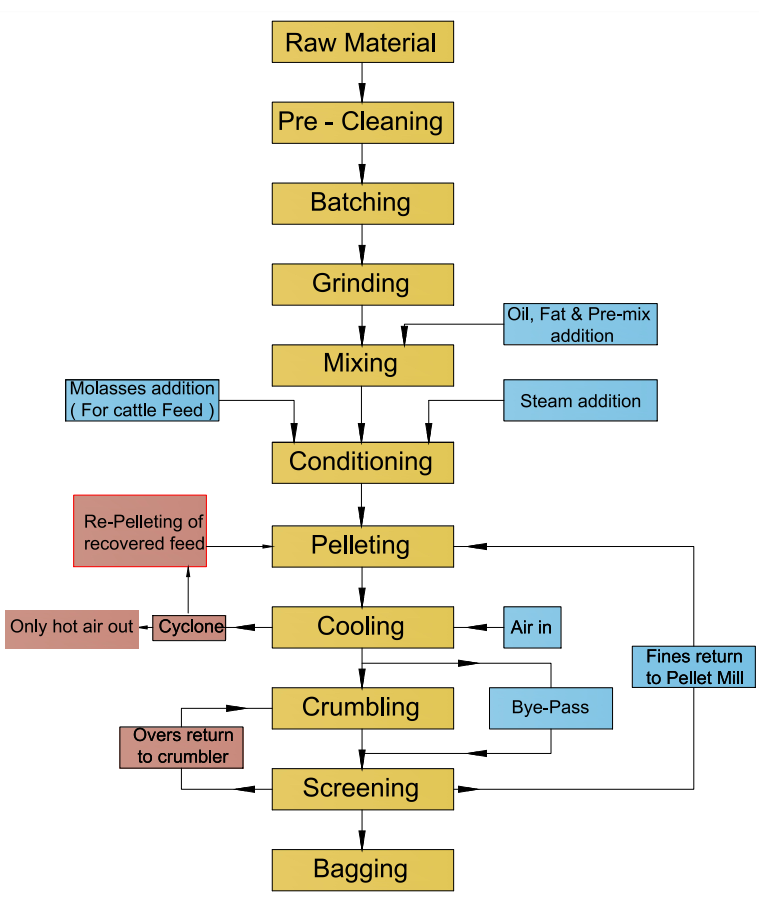

Flow Diagram