Complete Feed Mill Engineering

Specializes in design, engineering and manufacturing of Turnkey projects in poultry, cattle & aqua feed

About Lark Engineering

lateral thinking rather than thinking in a conventional way ”

"Innovation is thinking absolutely on different terms and having

lateral thinking rather than thinking in a conventional waylark engineering"

LARK

It was the year 1994 when it entered into Feed machinery market and manufactured its first small 2 H.P. Hammer mill. Over a period the company has come a long way and today we have more than 4200 installations all over the country and abroad which include from a single machine to fully automatically computerized projects.

LARK

It was the year 1994 when it entered into Feed machinery market and manufactured its first small 2 H.P. Hammer mill. Over a period the company has come a long way and today we have more than 4200 installations all over the country and abroad which include from a single machine to fully automatically computerized projects.

Lark Competences

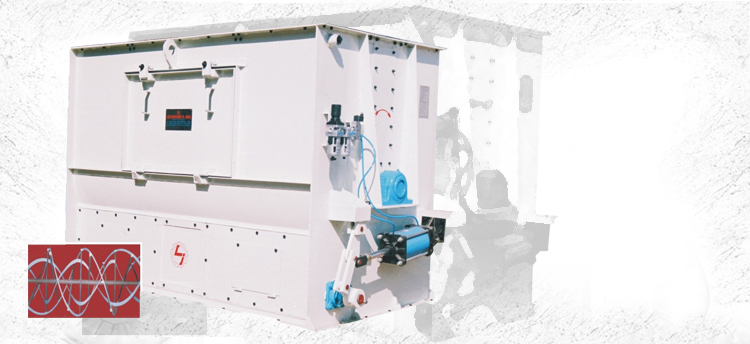

Lark has a separate R&D team and has good investment in time and money for its research programs. The results we have achieved are many, but to name a few are our patents applied in Hammer mill, Double Ribbon Screw Mixer in machines and in plants, designing cost effective pellet plant using minimum space, height, structure, power that reflects our capability.

We have state-of-the-art manufacturing facility. The division has comprehensive quality assurance system which ensures that products are backed by the best of quality processes and raw materials, and measure up to world class standards.

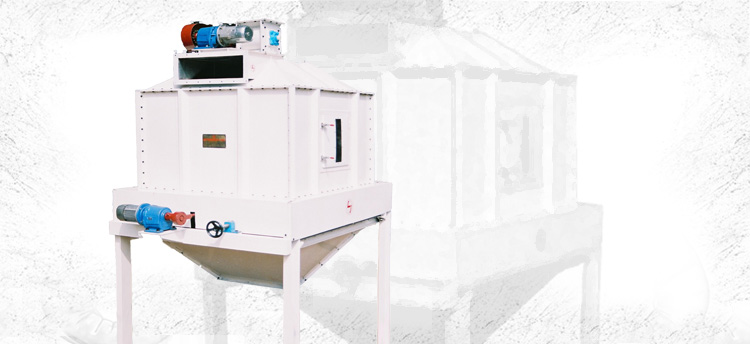

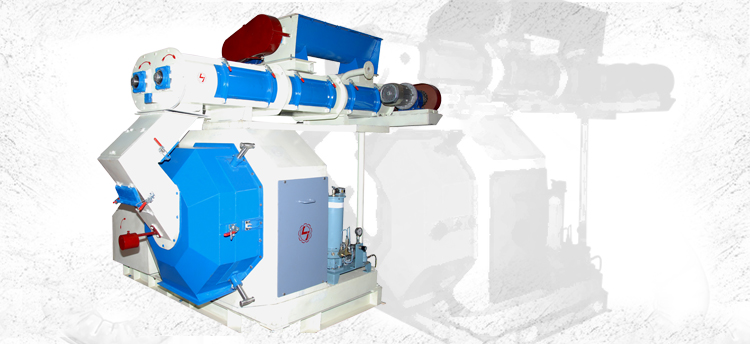

Our Products

Our Products

Our Worldwide Presence

Lark Engineering is deeply committed to global partnerships, providing solutions and services to valued

customers, with an international reach and presence, world-class capabilities and capacities, widespread

experience and expertise and best-in-class systems.

02

Patents

18+

Countries

140+

International Installations

3500+

National Installations

5000+

Satisfied Customers

Our Worldwide Presence

Lark Engineering is deeply committed to global partnerships, providing solutions and services to valued

customers, with an international reach and presence, world-class capabilities and capacities, widespread

experience and expertise and best-in-class systems.

02

Patents

18+

Countries

140+

International Installations

3500+

National Installations

5000+

Satisfied Customers

Our Projects

Customer says

Unnat feeds started 4-6 mash feed plant in 1995 , pellet project in 2007 . Still using the same mixer installed in the year 1995 ( life of gear box more than 20 years)

-Unnat Feeds

Customers Says

Under same feed formulation & operational parameters daily feed intake per bird is 117 grams as compared to 125 grams in other nearby farms

-Hiren patel ,Narayan Poultry , Gujarat

Customers Says

Power consumption per ton of feed is coming around 23 units / ton in poultry & 21.5 units per ton in cattle feed , which is lowest comparing to all other feed mills in north india.

-AFI Khanna

Customers Says

Maintenance cost + consumable cost of spare parts is coming around 32 rs /ton of feed which is lowest in all nearby projects.

-SKKF Feeds, Panipat

Customer Says

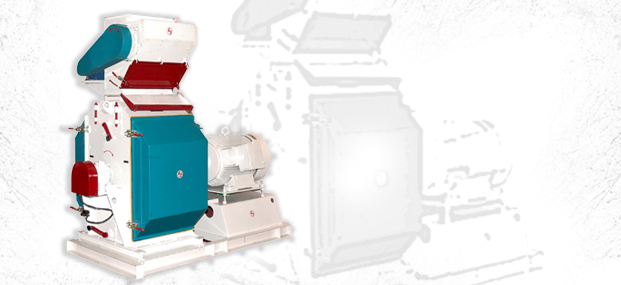

Getting more than 85 % millet grinding in lark hammer mill.

– Mr. Rajiv Juneja – Karnal

Customers says

There is 1 % increase in hatchability after using lark pre-mixer.

-Dr Dass, Bhairbi Agro, Bubhaneshwar

Video Gallery

300 TPD Cattle Feed Plant with Latest Technology

Hammer Mill

Pellet Feed Plant

There is 1 % increase in hatchability after using lark pre-mixer.

Getting more than 85 % millet grinding in lark hammer mill.

Maintenance cost + consumable cost of spare parts is coming around 32 rs /ton of feed which is lowest in all nearby projects.

Power consumption per ton of feed is coming around 23 units / ton in poultry & 21.5 units per ton in cattle feed , which is lowest comparing to all other feed mills in north india.

Video Gallery

There is 1 % increase in hatchability after using lark pre-mixer.

Getting more than 85 % millet grinding in lark hammer mill.

Maintenance cost + consumable cost of spare parts is coming around 32 rs /ton of feed which is lowest in all nearby projects.

Power consumption per ton of feed is coming around 23 units / ton in poultry & 21.5 units per ton in cattle feed , which is lowest comparing to all other feed mills in north india.

Video Gallery

Our Clients